|

Product Details

Home>

Product Details

|

- Product Introduction

Heat Shrink Cable Closure for Pressurised Cable Jointing

Wraparound Reinforced Heat-Shrinkable Closure

for pressurised Telephone Networks

Introduction of Product

1) Application: Widely used in pressurized telephone network for the protection of cable joints.

(1). Wraparound; Fiber reinforced; Suitable for aerial, buried and ducted applications; applicable temperature range: -40~80°C.

(2). Glass composite structure gives excellent split resistance and good performance under high mechanical pressure.

(3). Inner layer is strong hot-melt adhesive to ensure high sticky capacity. Closures have good tightness under high & low temperature.

(4). The kit contains a range of fully interchangeable air fittings, which can be incorporated in the closure.

(5). Two white lines under channel and thermo-sensitive paint on the sleeve can assure proper installation.

(6). Installation is easy and can apply to different sizes cables.

2) The reinforced closures have been developed to meet stringent demands in cable networks.

3) For this Purpose, a PE with fibre has been integrated in the heat-shrinkable sleeve.

4) This increase the split resistance during shrinking and its mechanical strength.

5) The inner side of the sleeve is coated with hot-melt adhesive which provides a watertight and secure bonding to plastic and metal-sheathed cable.

6) >suitable for unpressurized cables, aerial, buried or ducted, non-filled or jelly-filled,

7) with metal or polyethylene sheaths.

8) >Of super composite fibre structure and secondary sealing, with excellent mechanical strength, tear-resistant, shrinkage and resistance to weathering;

9) >The sealing employs high-quality imported Germany Henkel gel;

10) >Offers quick and easy application using an innovative closure mechanism;

11) >The white line on the inner side of the rail bar and heat sensitive paint on the exterior of the product may guide the proper operation;

12) >Minimum fully recovery temperature: 120℃;

13) >Standard color: Black.

14) Character:

15) resistance to any type of flame and mechanical abuse during and after the installation.

16) free of defects, pinholes, bubbles, cracks or inclusion visible with the unaided eyes.

17) internally coated with a flexible, heat-activated adhesive which will melt and adhere to the cable sheath to form an air and water proof seal.

18) The sleeves coated externally with a heat-sensitive thermo chromic indicator which will change colour when adequate heat has been applied.

19) not change to its original colour upon cooling or when placed in contact with water

20) The heat-sensitive thermo chromic not emit toxic fume when heated

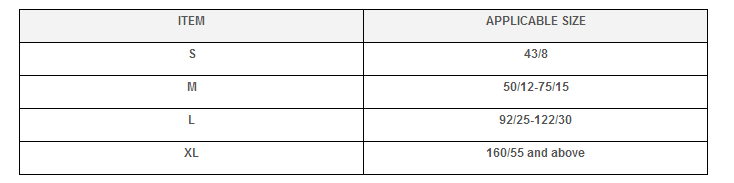

Product Size Table:

Remarks: other sizes, are available on customer requirements.

Logo can be printed on customer requirements

Metal canister/Plastic liner /cardboard liner / size, material are available on

customer requirements

heat shrinkable closure components include the straight/Branch jointing accessories

1 Heat shrinkable sleeve

2 Metal canister/Plastic liner /cardboard liner /

3 stainless steel channel clip

4 Self adhering aluminum closing strip

5 Nylon blinding strip

6 branching clips

7 abrasive strip

8 cleaning tissue, shielding wire

9 branch-off kit

10 PVC adhesive tape

11 aluminum foil

12 Installation procedure

13 Desiccants

14 Insulation Paper

15 Measuring Aid/Bond Line Gauge

BRANCH OFF CLIP

Description

The branch off clip are made of corrosion resistant aluminum alloy and coated with epoxy. The branch off clip shall have three fingers, the middle one coated with hot melt adhesive identical to that on the Thermo shrink sleeve. The adhesive on the branch off clip shall however, have a different colour to that of the Thermo shrink sleeve adhesive and thus give a visual indication to the jointer of correct adhesive flow and scaling of the branch.

Features

1. The branch-off clip provides high performance cable branching technique

2. Easy to install.

Product Size Table

ALUMINIUM CANISTER

Description

The aluminum canister are comprise of two performed half shells that can be hinged and fitted around the cable splice. The aluminum canister can provide adequate structural strength to avoid collapsing during installation. Finger –like formation shall be provided at the ends of the canister such that, when bent, it will give a smooth transition over the cable. The aluminum canister shall provide adequate structural strength to avoid collapse during installation.

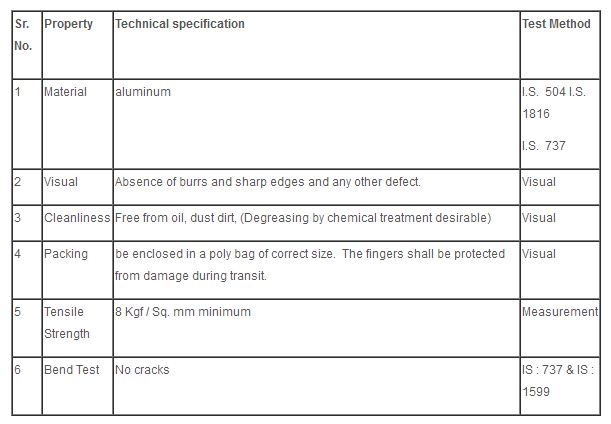

Technical specification

SHEATH CONNECTOR ASSEMBLY

Description

The sheath connector assembly consists of three items, viz. an insulated stranded copper wire with connecting elements on both sides, a small wire of the same description with connecting element on one side only and a bridge connector for jointing the two wires. The connecting element is made of phosphor bronze, hacked by a non-corrosive metal back-plate strongly pressed to it and also crimped to the connecting wire. The element has an opening provided with toothed jaws into which the cable sheath can be inserted and crimped using ordinary pliers. The toothed jaws when cripped, bite through the cable sheath to make a good low-resistance metallic contact with the sheath of the cable. In order to inter-connect the sheath connector wires in branch joints, the bridge wire connector is used in conjunction with the single ended connector assembly.

Technical specification

The sheath connector assembly conforms to the following requirements: